Phone:

+86 18680402057

sandyht@weldomachinery.net

The Cost of Making Enamel Pins in 2025/2026: Full Breakdown

The demand for custom enamel pins has surged, but understanding the cost breakdown of producing enamel pins in 2025/2026 can be a challenge. The cost is influenced by several factors, including design complexity, materials, machinery, and order quantity. This guide will take you through each factor to provide a clear breakdown of the cost to make enamel pins.

1. Design Complexity and Labor Costs

The design process is one of the most important factors influencing the cost of enamel pin production. A more detailed design requires additional labor and more advanced machinery, such as an Uncle Sam enamel pin badge filling machine or an animal enamel pin badge filling machine. These designs often demand higher precision, which can increase production costs. For example, if you want to create a 4th of July American flag enamel badge filling machine pin, you’ll need to account for the intricate design that requires specialized equipment to produce vibrant and accurate results.

2. Material Selection

Material selection plays a significant role in determining the final cost of enamel pins. Common materials include zinc alloy, brass, and copper, but premium materials are often necessary for specialty designs. For instance, if you’re designing a LGBTQ accessories filling machine pin, you might opt for materials that offer durability and vibrant color representation. The material's quality impacts the final product’s durability and aesthetic appeal, which affects the cost.

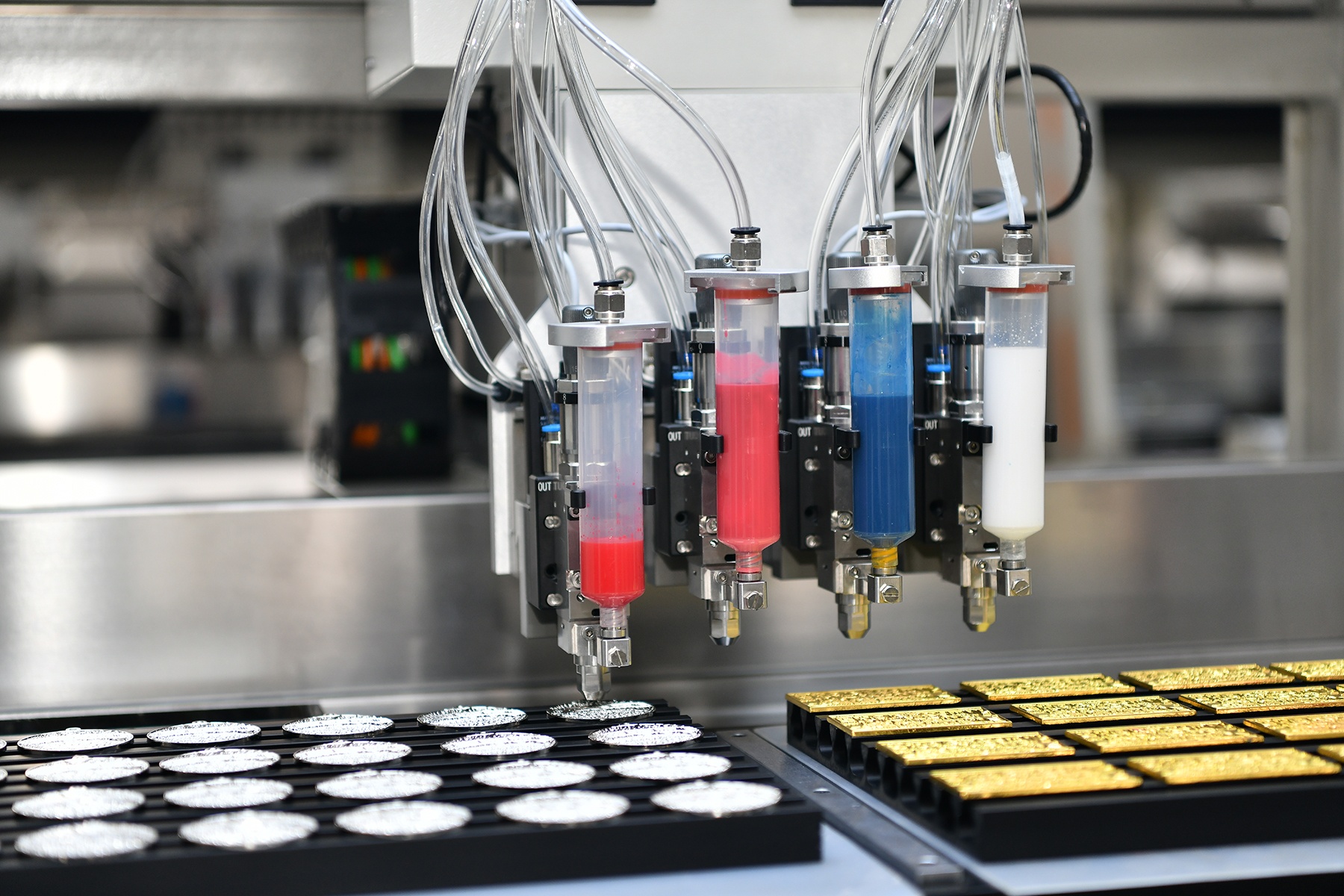

3. Machinery Costs

Investing in the right machinery is crucial for producing high-quality enamel pins. Machines like the Collectible enamel pin badge Disney filling machine or Enamel pin badge with emoji design filling machine are essential for creating detailed designs at scale. While these machines come with significant upfront costs, they enable efficient mass production and can help reduce the per-unit cost for larger orders. However, smaller batches or custom designs often incur higher costs per pin due to the setup time and machine calibration required.

4. Production Volume and Unit Costs

The volume of enamel pins you want to produce also directly affects the unit price. Large orders benefit from economies of scale, reducing the overall cost per pin. For example, a large production run of Uncle Sam enamel pin badge filling machine designs or animal enamel pin badge filling machine designs results in a lower per-unit cost. On the other hand, if you’re only producing a limited edition of enamel pins, like a 4th of July American flag enamel badge filling machine pin, the per-unit cost is generally higher due to the higher setup fees and lower production volume.

5. Conclusion

In summary, the total cost of producing enamel pins in 2025/2026 depends on several factors: design complexity, material choice, machine investment, and production volume. Machines such as the LGBTQ accessories filling machine and Collectible enamel pin badge Disney filling machine are essential for achieving high-quality results, but they come with their own costs. Understanding these factors will help you manage your enamel pin production budget effectively and create a product that meets your vision and financial expectations.

READ MORE:

- Understanding the Demand for Custom Metal Tags

- Exploring Innovations in the Metal Tags Market

- How Big is the Metal Tags Market?

- Enamel Pin Production Costs in 2025/2026: A Comprehensive Guide

- The Role of Innovation in the Growing Metal Tags Market

- The Growing Demand for Personalized Pet Products and the Metal Tags Market

- Comprehensive Enamel Pin Production Cost Breakdown for 2025/2026

- Innovations Driving Growth in the Metal Tags Market

- The Expanding Role of Metal Tags in the Pet Industry