Phone:

+86 18680402057

sandyht@weldomachinery.net

How Much Does It Cost to Make Enamel Pins in 2025? A Breakdown of Key Expenses

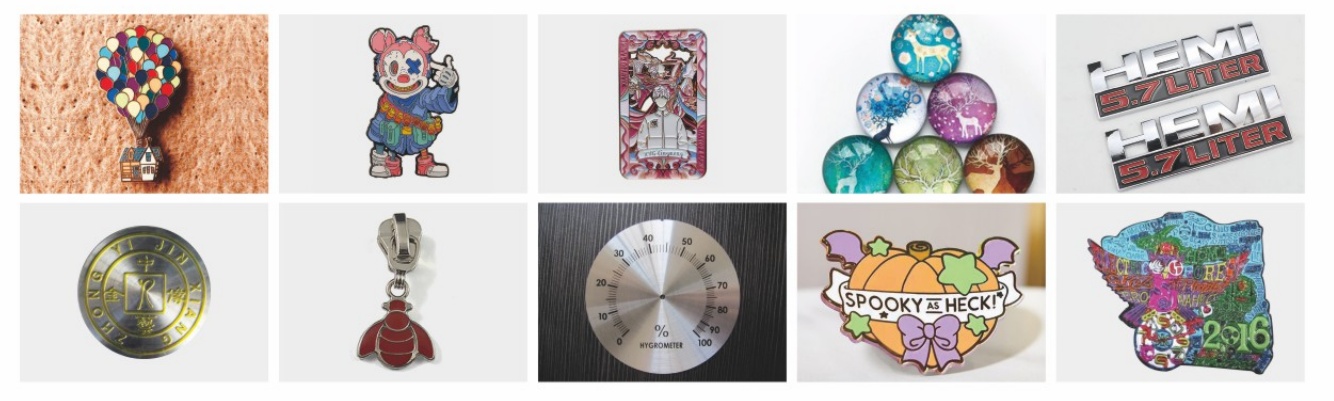

The process of making enamel pins is not only an art form, but also a significant investment in both time and money. If you are planning to make enamel pins in 2025, it's important to understand the key costs involved, including machine costs, materials, design, labor, and shipping. In this guide, we will break down these costs and explore how to make the process as cost-effective as possible.

1. Machines for Enamel Pin Production

One of the most significant expenses in enamel pin production is purchasing the right machines. For example, an Uncle Sam enamel pin badge filling machine is a great investment for high-quality, patriotic designs. These machines can range from $3,000 to $10,000 depending on the model and capabilities. Additionally, you might need an animal enamel pin badge filling machine if you want to diversify your designs. These machines are designed to handle various pin shapes and sizes, which can increase initial costs but provide more versatility.

2. Design and Material Considerations

Creating a design for your enamel pins is a key part of the process and can influence the overall cost. The cost of custom designs typically ranges between $100 and $500, depending on complexity. Additionally, the material choice will affect the price. For example, an American Independence enamel pin filling machine might require more specialized materials for the pins. The metal, enamel, and color options all impact the production cost, and premium materials like brass can raise the price.

3. Labor and Production Time

The labor cost for producing enamel pins can vary based on the scale of production. Smaller batches may require manual labor, which is time-consuming and more expensive. For larger quantities, you can use automated production lines, like the LGBTQ accessories filling machine, to streamline the process and reduce labor costs. Depending on the scale, labor can account for up to 40% of the total production costs.

4. Bulk Production Savings

When producing enamel pins in bulk, you'll enjoy cost savings due to economies of scale. Whether you're using a collectible enamel pin badge Disney filling machine or another type of equipment, producing in larger quantities can significantly lower the cost per pin. Bulk production helps reduce the labor time and machinery use, which leads to overall savings.

5. Shipping and Packaging Costs

Don’t forget about shipping and packaging, which are often overlooked in cost calculations. Packaging can range from $0.50 to $3.00 per pin depending on the type of materials you use. Eco-friendly packaging is a good option for customers who prefer sustainability, though it can come at a slightly higher price. Shipping fees will also depend on the weight of the order and the shipping method, ranging from $50 to $500 or more depending on the size of the order.

SEO Keywords:

- uncle sam enamel pin badge filling machine

- animal enamel pin badge filling machine

- American Independence enamel pin filling machine

- LGBTQ accessories filling machine

- Collectible enamel pin badge Disney filling machine

- Enamel pin badge with emoji design filling machine

READ MORE:

- Enamel Pin Production Cost Breakdown in 2025/2026

- Understanding Enamel Pin Production Costs in 2025/2026

- How Big is the Metal Tags Market? Exploring Key Trends and Innovations

- The Ultimate Guide to Enamel Pin Production Costs in 2025/2026

- Cost Breakdown: Making Enamel Pins in 2025/2026

- Understanding the Costs of Making Enamel Pins in 2025/2026

- How Much Does It Cost to Produce Custom Enamel Pins in 2025/2026?

- How Much Does It Cost To Make Enamel Pins in 2025/2026? The Full Guide And Breakdown!

- The Full Cost Breakdown of Making Enamel Pins in 2025: Everything You Need to Know

READ MORE:

- Sustainability in the Metal Tags Market

- Revolutionizing Metal Tags with Personalization

- Industrial Uses of Metal Tags

- Factors Driving the Growth of the Metal Tags Market

- How Big is the Metal Tags Market?

- Understanding the Cost of Making Enamel Pins in 2025: An In-Depth Look

- How Much Does It Cost to Make Enamel Pins in 2025? A Comprehensive Guide

- Exploring the Future of the Metal Tags Market with Advanced Technology

- The Role of Technology in Expanding the Metal Tags Market