Phone:

+86 18680402057

sandyht@weldomachinery.net

Cost Breakdown for Making Enamel Pins in 2025

Enamel pins remain a popular product in 2025, but how much does it cost to produce them? In this article, we will give you a breakdown of the costs involved in producing enamel pins, focusing on the key machinery needed, such as the uncle sam enamel pin badge filling machine, animal enamel pin badge filling machine, and other essential equipment.

1. Design and Artwork Costs

The first step in making enamel pins is the design process. Depending on the intricacy and detail of the design, the cost for custom artwork can range from $50 to $500. Once the design is finalized, it's sent to production to create a mold for the pins.

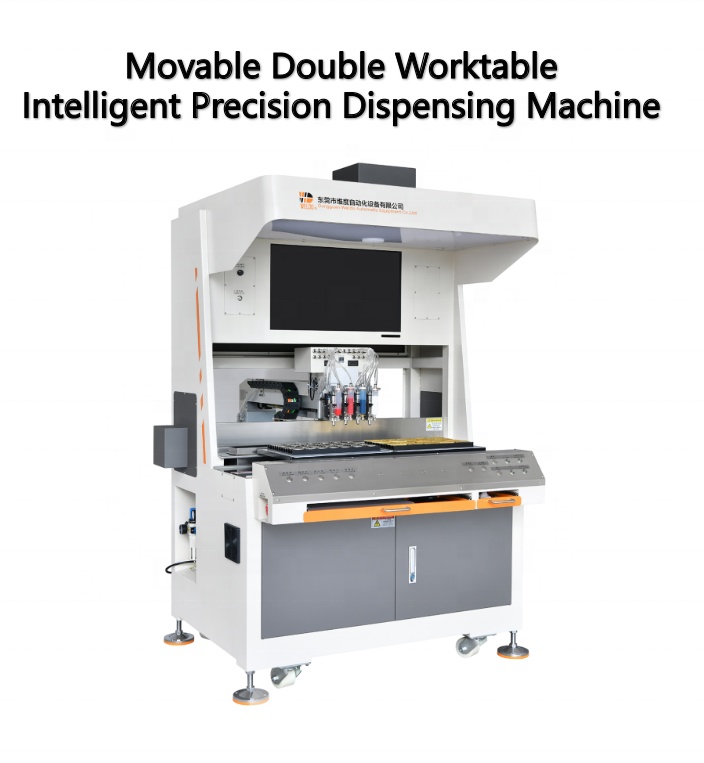

2. Cost of Equipment and Machinery

The machinery needed to produce enamel pins is a significant expense. The uncle sam enamel pin badge filling machine is specifically used for pins with American-themed designs, making it a popular choice for patriotic designs. The animal enamel pin badge filling machine is another essential piece of equipment, commonly used to make animal-themed enamel pins. The cost for these machines can vary, with prices ranging from $3,000 to $10,000 depending on the brand and features.

3. Production and Material Costs

Once you have your design and machinery ready, the next step is production. The Cute enamel button pin filling machine is commonly used for creating smaller, more detailed designs. The cost of production depends on factors such as batch size, material quality, and the intricacy of the design. Larger orders generally lower the cost per unit.

4. Labor Costs

Labor is another key expense when it comes to enamel pin production. Each pin requires labor for tasks such as quality control and finishing. The cost for labor varies depending on location and the complexity of the process. Manual work adds to the overall cost, but is necessary to ensure the quality of the finished product.

5. Specialized Equipment for Niche Designs

If you are creating specialty pins, the cost of machinery can increase significantly. For example, the LGBTQ accessories filling machine is designed to create enamel pins that represent LGBTQ culture, while the Collectible enamel pin badge Disney filling machine is used for Disney-themed pins. These specialty machines can increase production costs, but they are essential for producing niche designs.

Conclusion

Overall, producing enamel pins in 2025 can cost between $500 and $5,000, depending on factors like the design, machinery, and batch size. The American Independence enamel pin filling machine is great for creating patriotic designs, while other machines are necessary for more specialized products.

READ MORE:

- Innovations in Enamel Paint Filling Machines: Transforming the Custom Metal Tags Market

- Enamel Pin Production Costs in 2025: What You Need to Know

- How Much Does It Cost To Make Enamel Pins in 2025? A Detailed Breakdown

- The Impact of Enamel Paint Filling Machines on the Future of Custom Metal Tags

- The Role of Enamel Paint Filling Machines in the Growing Custom Metal Tags Market

- The Future of Custom Metal Tags: Embracing Enamel Paint Filling Machines

- Innovations Driving the Growth of the Custom Metal Tags Market

- The Impact of Enamel Paint Filling Machines on the Custom Metal Tags Market

- The Growing Market of Custom Metal Tags